Ship

Chris-Craft Cobra pt 2

30 - July - 2016 - 12:43

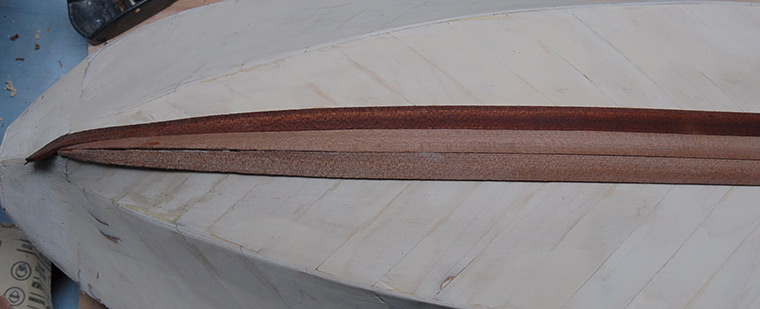

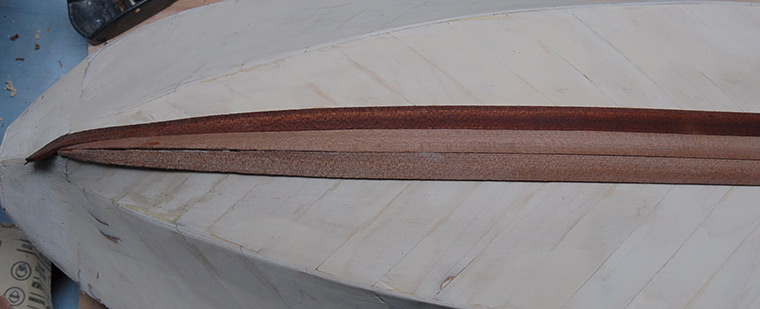

In the last post, I had just wrapped up the under-planking. Next came the mahogany planking. I began on the keel, running a plank up each side of the center line on the bottom. I also soaked some of the planks, so that they would be easier to bend at the front. Below you can see the darker plank (dark because it is wet), bent around the front of the keel.

After a few rows of planks from the center, I then added one that runs along the edge that forms the border between the bottom and the sides. Having that plank in place gave me something to fit the bottom planks to, so there isn’t a gap.

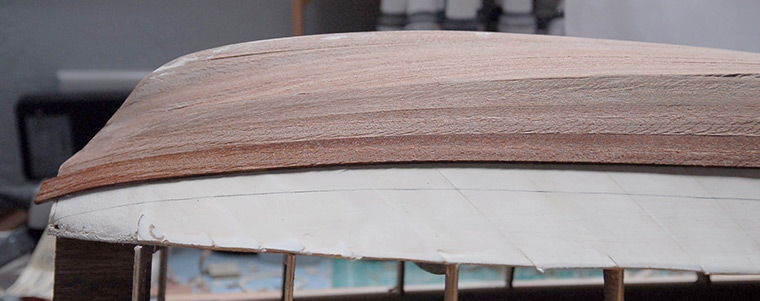

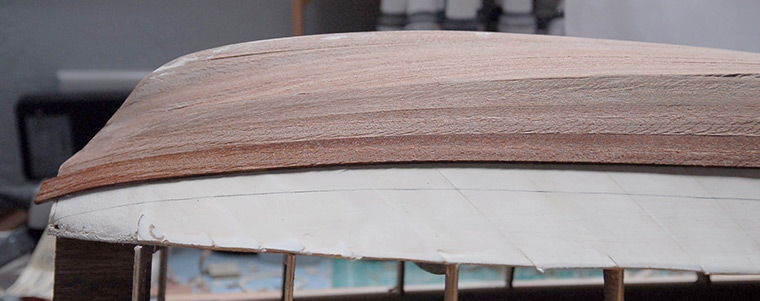

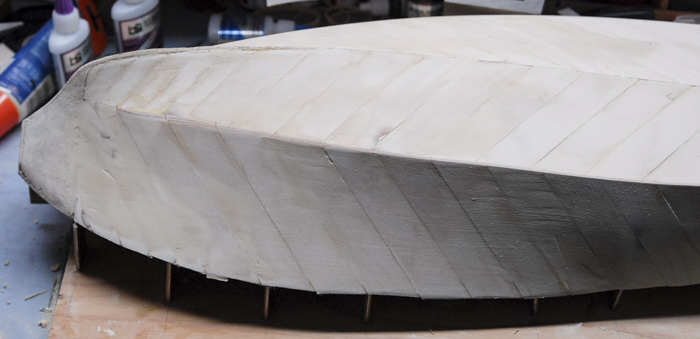

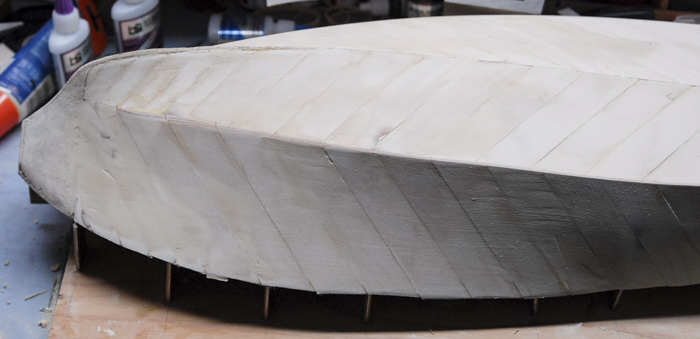

Below you can see the bottom planking done. The planks are just glued on with thick CA glue, so they go on fairly quickly.

Below you can see a detail shot of the front. I wasn’t too careful about the fitment on these planks, as they will be below the waterline and therefore painted. With a little filler and sanding, this area will be nice and smooth before it gets painted.

The planking continued on the sides of the boat. The planks were long enough to span the length of the boat, so attaching them really just consisted of tracing a line along the edge of each plank on the hull (seen below), and then using that line as a guide for where to apply some glue. With the glue in place, then I can just hold the plank in place until the glue sets.

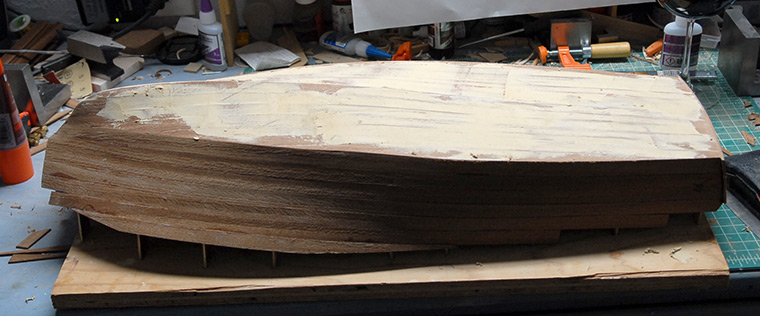

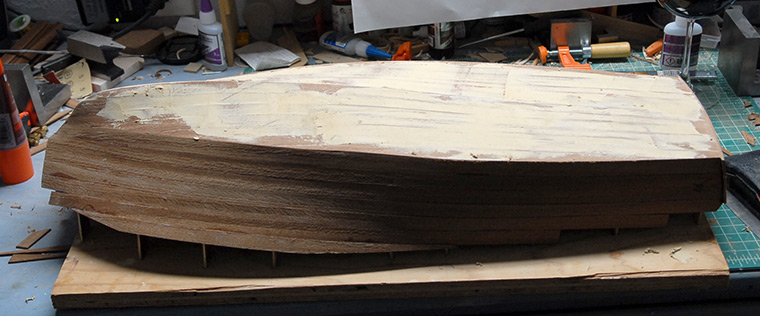

Below you can see all the bottom and side planks in place.

Here is a close-up showing the relatively rough surface of the planks. This will take quite a bit of sanding later to get it smoothed out.

With all the planking in place, I applied a coat of the wood filler to the lower parts of the hull. This is the area that will later be painted, so having a smooth surface is more important than having good looking wood.

Below you can see the nose of the hull after a bit of sanding and refining of the center line.

It was also at about this point that I realized that maybe soaking the big mahogany planks was not the best thing to do. It seems that while the planks being wet made them easier to bend around a few curves, it also made them swell just a bit. Once the planks had been on the hull for a few days and had dried out, they shrunk back to their original size, leaving a few gaps between the planks. I’m hoping that these will be filled in a bit later on, once I put a bunch of coats of spar varnish on the hull.

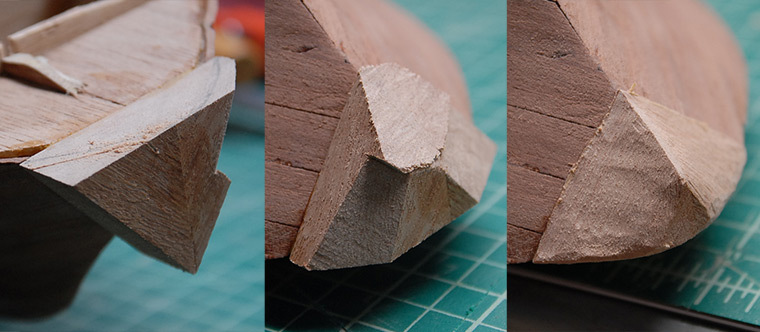

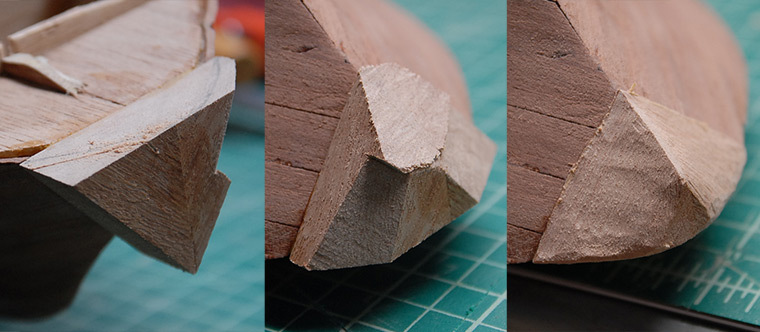

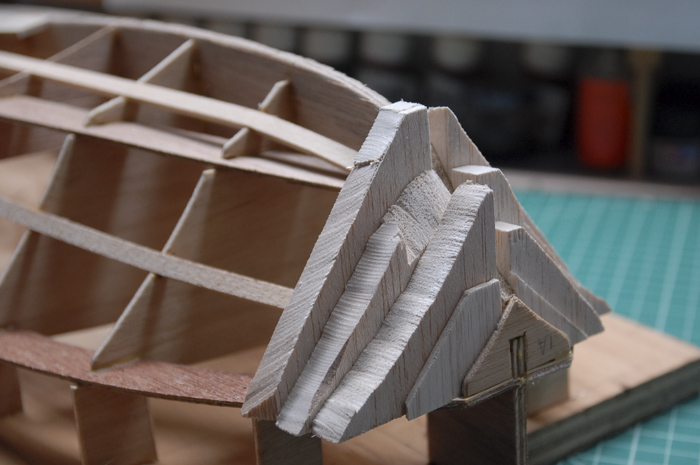

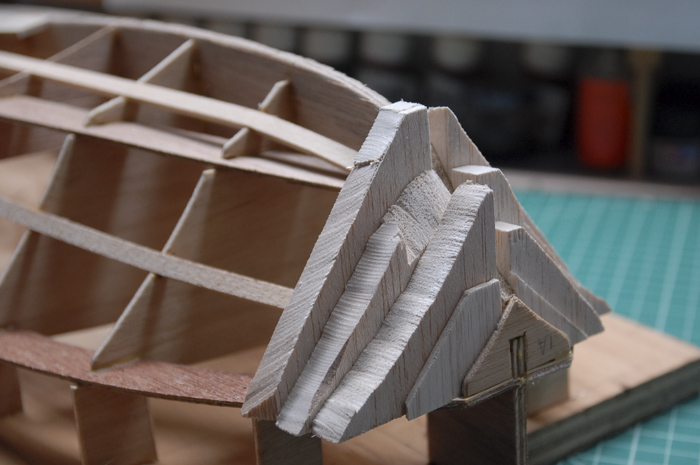

Next up was carving the nose from a block of mahogany. Below you can see the starting point, which was two triangles glued together, a mid point, when I had sawn off big chunks for rough shaping, and the point at which I had finished the rough shaping using a Dremel and sanding drum.

In order to reduce the mess from the sanding, I had some luck making a makeshift dust collection system using out vacuum cleaner hose positioned near the sanding. Below you can see an action shot of the sawdust coming off of the sanding drum and into the hose. It looked cool, so I took a photo :)

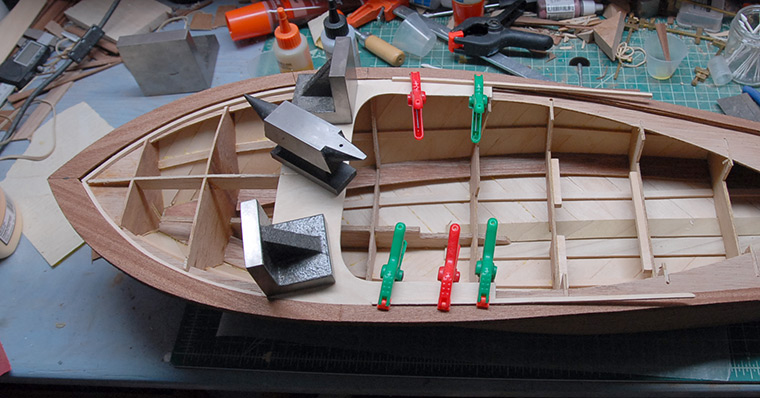

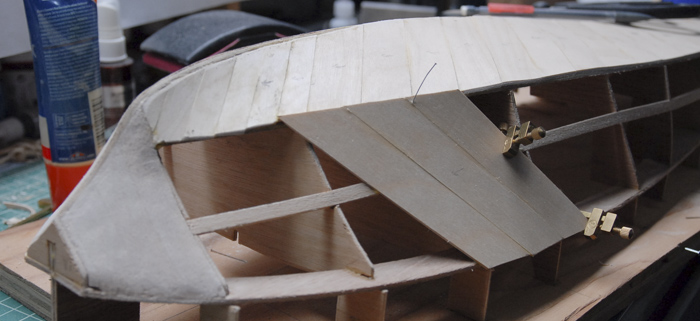

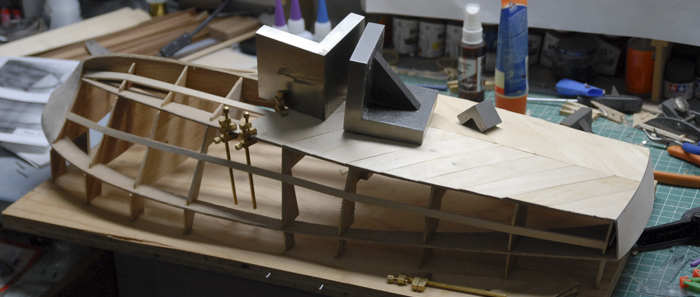

That completed the underside of the boat. The next step was to cut it off of the build board, sand the ribs flush with the top surface and then start adding the top deck components. Below you can see the edge parts glued in place. This was, unfortunately, where I made a bit of a mistake, placing the side strips a little bit too far inboard. I didn’t notice the misplacement until later in the build, though.

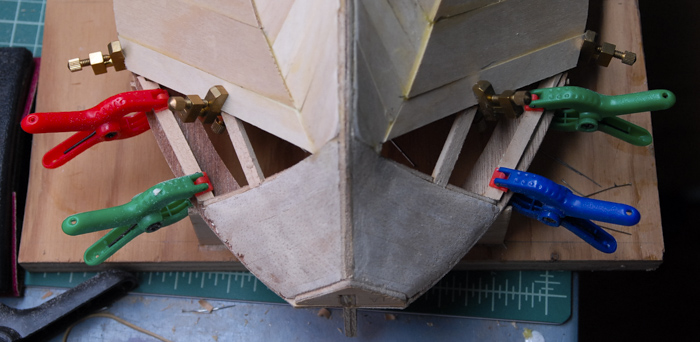

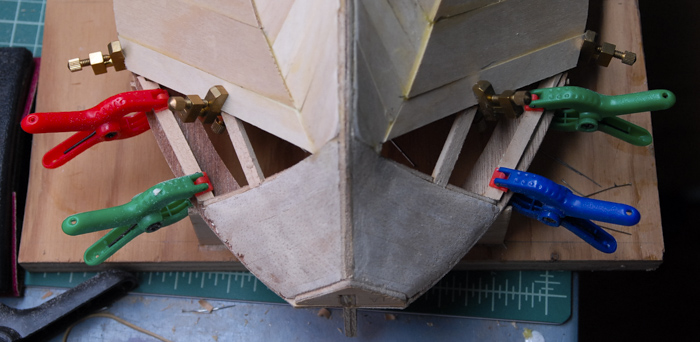

The side strips consist of three layers, each layer overlapping the others differently. Below you can see the second layer being held in place while the glue dries.

There is a strip that runs along the inside of the mahogany parts that provides support for the decking later. Below you can see it being glued in place.

In gluing the above strip in place, I realized my mistake. The rear edge strip was in the correct place, but when I glued the side strips on, I had aligned the outside edges with the outside of the rear strip, when I SHOULD have aligned the inside edges. Once I discovered this, I found that I couldn’t pry off the side strips without doing lot of damage, so I opted instead to make adjustments to the build as I went, in order to compensate for the misalignment. The first thing I had to do was add a few extra strips to the back in order to even out the alignment of the inside edge. Below you can see the two additional strips, before sanding.

While there will need to be more adjustments later, the next few steps were fairly straightforward. Below you can see some decking glued in place, forming the front of the cockpit surround.

Front sub-planking in place, using the same techniques as the lower hull:

I order to provide support for the rear and side decks, I needed to add some support ribs. Theses were just 1/8” basswood, cut to length and tapered a bit so that there will be a bit of a slope to the decks.

Below you can see the side/rear sub-decking in place. I had to do a good deal of trimming and fitting to this piece in order to fit it into a space that is slightly smaller due to my additional thickness on the rear edge piece.

Finally, once the sub-deck was in place, I could start to add the final top decking layer. Below you can see the current state of the boat. Because the side rails should have been pushed just a bit back and out, the center basswood part didn’t reach the full length of the front deck. This meant that I had to add a little piece to extend it, which will be sanded and integrated more later. The thicker rear edge rail also required that the large basswood part be shortened slightly, in order to match up with the edges of the cockpit and still just meet the rear edge. I ended up removing approximately 1/4 inch from the straight section along the edge of the cockpit. I may also need to shorten the plastic molded pieces that form the engine cover and fin, but I was already thinking of cutting those up in order to add opening engine bay covers, so that may not cause any problems.

That is where the project stands now. Next up is applying the striped mahogany and plastic decking, and then a bunch of sanding to even it all out.

Thanks for reading!

After a few rows of planks from the center, I then added one that runs along the edge that forms the border between the bottom and the sides. Having that plank in place gave me something to fit the bottom planks to, so there isn’t a gap.

Below you can see the bottom planking done. The planks are just glued on with thick CA glue, so they go on fairly quickly.

Below you can see a detail shot of the front. I wasn’t too careful about the fitment on these planks, as they will be below the waterline and therefore painted. With a little filler and sanding, this area will be nice and smooth before it gets painted.

The planking continued on the sides of the boat. The planks were long enough to span the length of the boat, so attaching them really just consisted of tracing a line along the edge of each plank on the hull (seen below), and then using that line as a guide for where to apply some glue. With the glue in place, then I can just hold the plank in place until the glue sets.

Below you can see all the bottom and side planks in place.

Here is a close-up showing the relatively rough surface of the planks. This will take quite a bit of sanding later to get it smoothed out.

With all the planking in place, I applied a coat of the wood filler to the lower parts of the hull. This is the area that will later be painted, so having a smooth surface is more important than having good looking wood.

Below you can see the nose of the hull after a bit of sanding and refining of the center line.

It was also at about this point that I realized that maybe soaking the big mahogany planks was not the best thing to do. It seems that while the planks being wet made them easier to bend around a few curves, it also made them swell just a bit. Once the planks had been on the hull for a few days and had dried out, they shrunk back to their original size, leaving a few gaps between the planks. I’m hoping that these will be filled in a bit later on, once I put a bunch of coats of spar varnish on the hull.

Next up was carving the nose from a block of mahogany. Below you can see the starting point, which was two triangles glued together, a mid point, when I had sawn off big chunks for rough shaping, and the point at which I had finished the rough shaping using a Dremel and sanding drum.

In order to reduce the mess from the sanding, I had some luck making a makeshift dust collection system using out vacuum cleaner hose positioned near the sanding. Below you can see an action shot of the sawdust coming off of the sanding drum and into the hose. It looked cool, so I took a photo :)

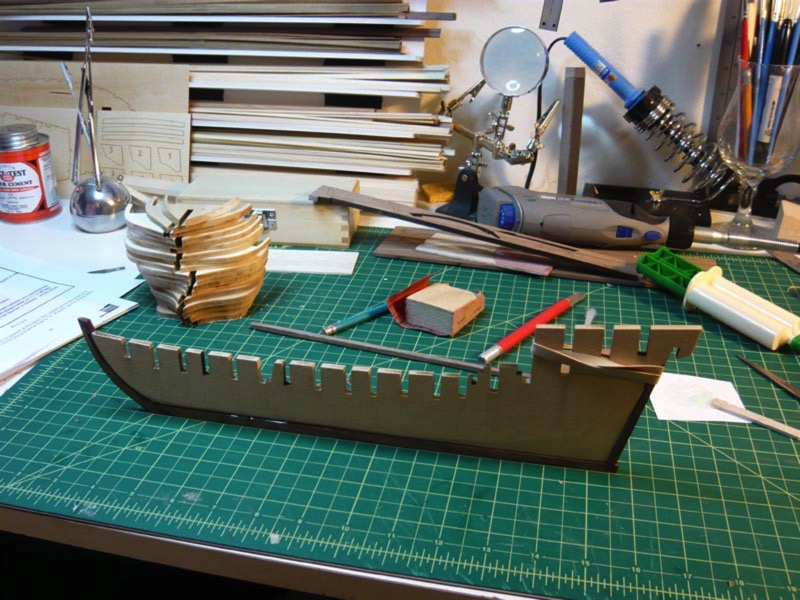

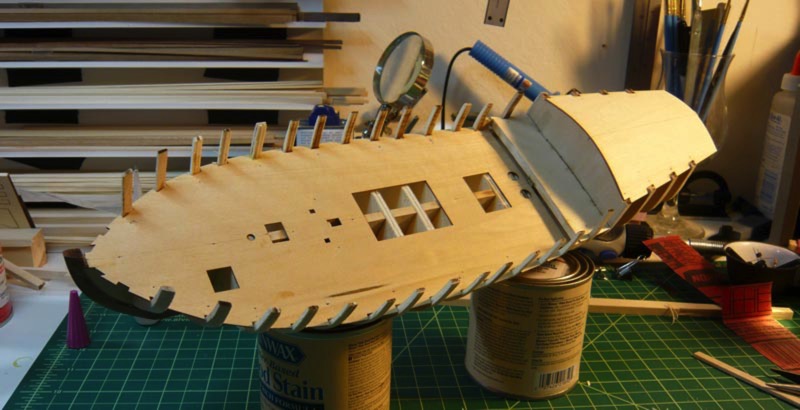

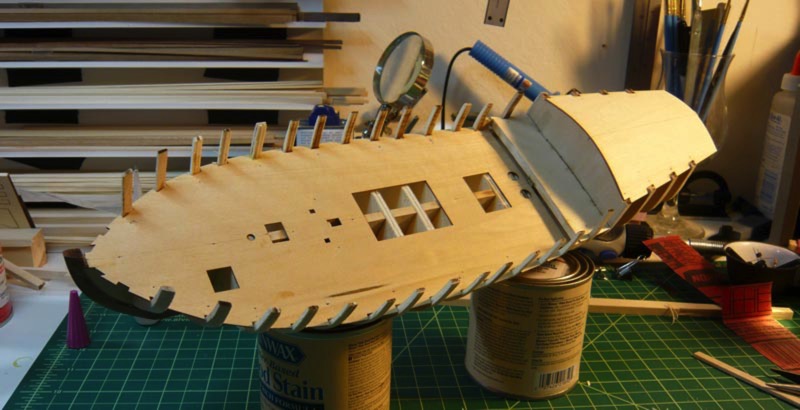

That completed the underside of the boat. The next step was to cut it off of the build board, sand the ribs flush with the top surface and then start adding the top deck components. Below you can see the edge parts glued in place. This was, unfortunately, where I made a bit of a mistake, placing the side strips a little bit too far inboard. I didn’t notice the misplacement until later in the build, though.

The side strips consist of three layers, each layer overlapping the others differently. Below you can see the second layer being held in place while the glue dries.

There is a strip that runs along the inside of the mahogany parts that provides support for the decking later. Below you can see it being glued in place.

In gluing the above strip in place, I realized my mistake. The rear edge strip was in the correct place, but when I glued the side strips on, I had aligned the outside edges with the outside of the rear strip, when I SHOULD have aligned the inside edges. Once I discovered this, I found that I couldn’t pry off the side strips without doing lot of damage, so I opted instead to make adjustments to the build as I went, in order to compensate for the misalignment. The first thing I had to do was add a few extra strips to the back in order to even out the alignment of the inside edge. Below you can see the two additional strips, before sanding.

While there will need to be more adjustments later, the next few steps were fairly straightforward. Below you can see some decking glued in place, forming the front of the cockpit surround.

Front sub-planking in place, using the same techniques as the lower hull:

I order to provide support for the rear and side decks, I needed to add some support ribs. Theses were just 1/8” basswood, cut to length and tapered a bit so that there will be a bit of a slope to the decks.

Below you can see the side/rear sub-decking in place. I had to do a good deal of trimming and fitting to this piece in order to fit it into a space that is slightly smaller due to my additional thickness on the rear edge piece.

Finally, once the sub-deck was in place, I could start to add the final top decking layer. Below you can see the current state of the boat. Because the side rails should have been pushed just a bit back and out, the center basswood part didn’t reach the full length of the front deck. This meant that I had to add a little piece to extend it, which will be sanded and integrated more later. The thicker rear edge rail also required that the large basswood part be shortened slightly, in order to match up with the edges of the cockpit and still just meet the rear edge. I ended up removing approximately 1/4 inch from the straight section along the edge of the cockpit. I may also need to shorten the plastic molded pieces that form the engine cover and fin, but I was already thinking of cutting those up in order to add opening engine bay covers, so that may not cause any problems.

That is where the project stands now. Next up is applying the striped mahogany and plastic decking, and then a bunch of sanding to even it all out.

Thanks for reading!

1955 Chris-Craft Cobra

15 - May - 2016 - 21:47

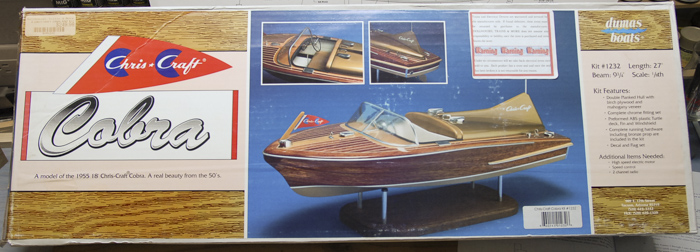

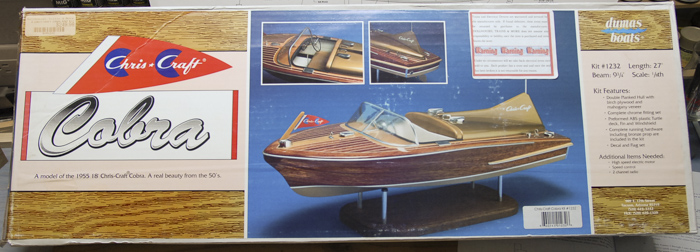

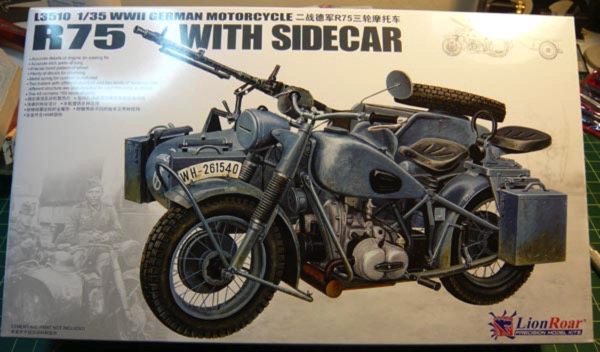

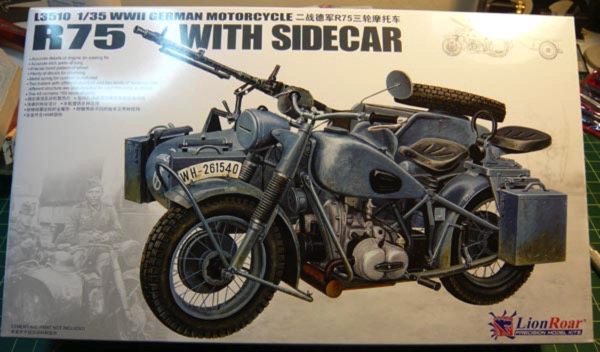

Back at the end of 2015, I was in Orlando, Florida, visiting Disney World (taking advantage of a perk of working for the mouse: free park entry!). One of the restaurants in Disney Springs (formerly Downtown Disney) was just FILLED with great looking large scale boat and ship models. I was inspired to take up a wooden model project again, except this time I wanted it to end up shiny. After a bit of research, I narrowed it down to a handful of possible kit options. Mostly I was looking at kits from Dumas, as they have some great looking Chris-Craft speedboat kits. I spent a Saturday morning making the rounds at my local hobby shops (living in the SF Bay Area, there are a few to choose from) and managed to find this kit:

With a length of 27 inches, it’s a fairly large scale project (at least for me and my limited building space).

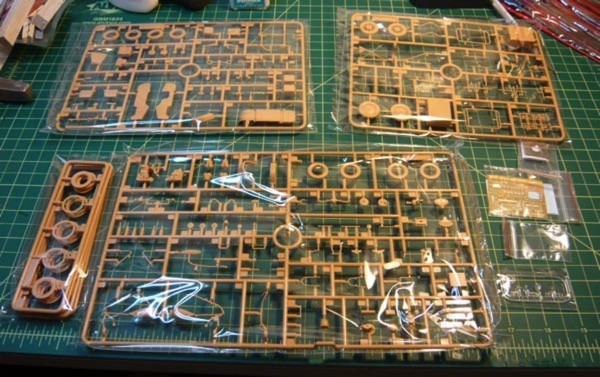

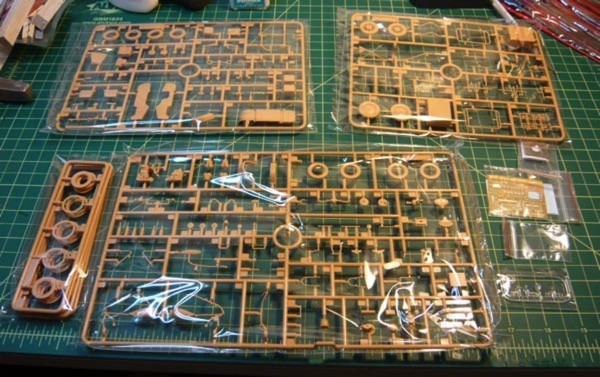

Like most kits of this type, it comes as a number of sheets of pre-cut parts, some strips of thin plywood, a bunch of strips of mahogany and bass wood, and some cast metal parts.

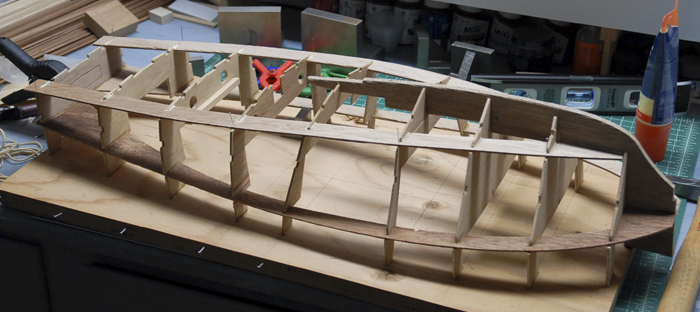

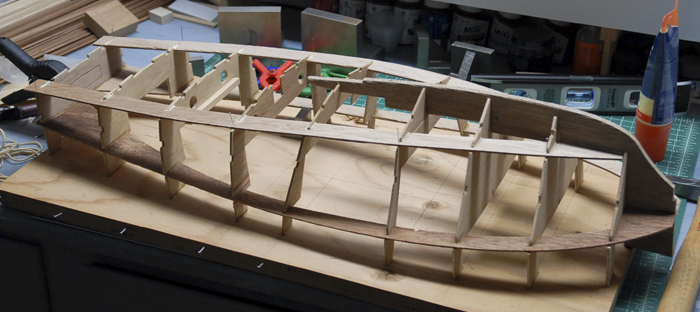

The instructions had me start by marking rib positions on a building board (spare plywood in this case) and then assembling and gluing the frame to the board.

That was followed by adding a few stringers and the keel boards on the bottom of the boat.

Because of the rapid change in shape between the first rib and the nose of the boat, the front is shaped from balsa. The kit came with a sheet of half-inch-thick balsa that was cut into triangles and glued in place. Below you can see the rough blocks glued in place. I had to use a little bit of spare balsa that I had laying around in order to fill the space all of the way (those thin sheets right at the front).

Below you can see the rough shaping. This was done using first a jewelers saw to cut off big chunks of the wood, then a sanding drum on a Dremel for fast shaping and then finally some 150 grit sandpaper for finer shaping.

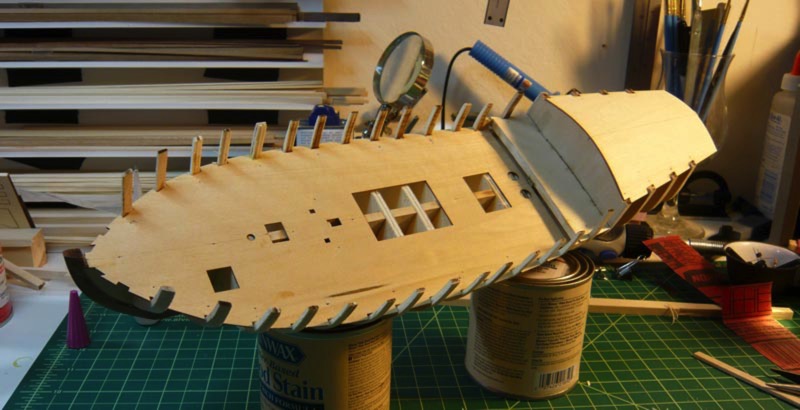

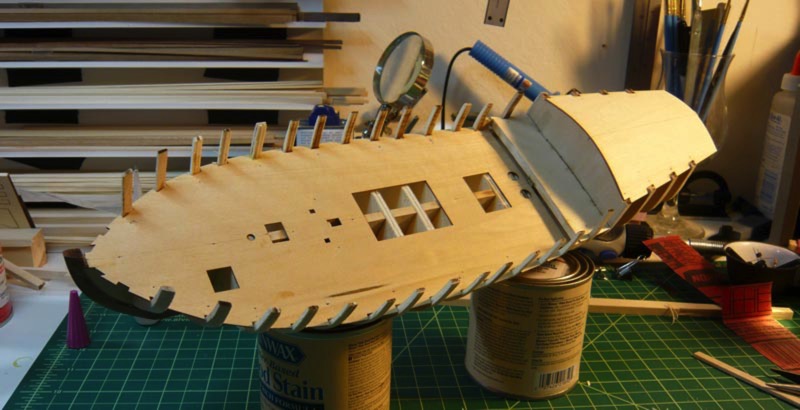

Next up was the under-planking. This consisted of 1/16 inch thick plywood strips that are laid diagonally on the bottom and sides of the hull. The instructions said to use a thick cyanoacrylate (super glue), but I found that when the strips needed to be bent a bit, the glue tended to not have the strength to hold the strips in place. I believe that this was mostly because there were fairly small areas in which the strips contacted the frame. I had actually started the planking and then found that I had started laying the planks going the wrong direction (dark spots in photo below was the glue that held them in place). When I discovered this, I tried to take those planks off and discovered that they came off so easily that I lost all confidence in the CA method.

I decided instead to try good ol’ yellow carpenter’s glue. This required that the strips be clamped in place while the glue dried. Once dried, though, the glue was strong and the connection between the strips and frame was solid. I ended up going with this technique for all of the under-planking. Below you can see the transom in place as well as the first few planks.

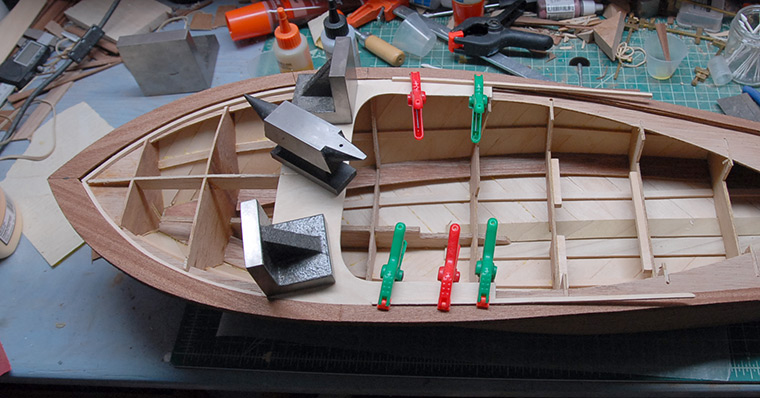

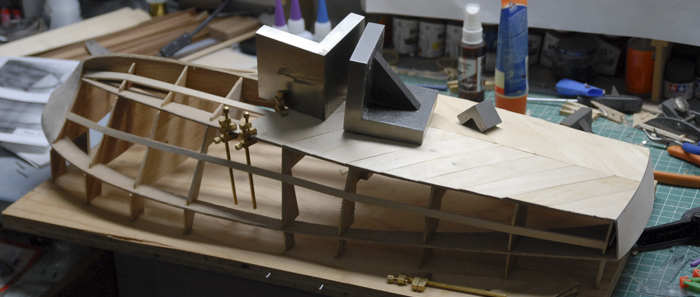

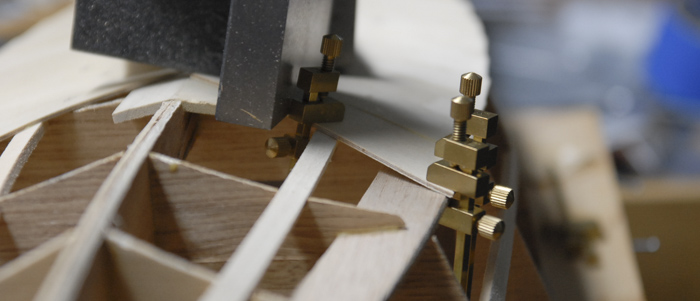

Below you can see some of the clamping and weighting I needed to do in order to hold planks in place while the glue dried. Those angle blocks weigh 3lbs each, and were providing a great deal of pressure on those planks.

A closer view of the same setup.

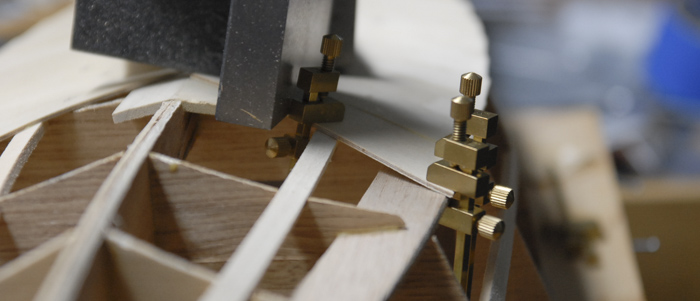

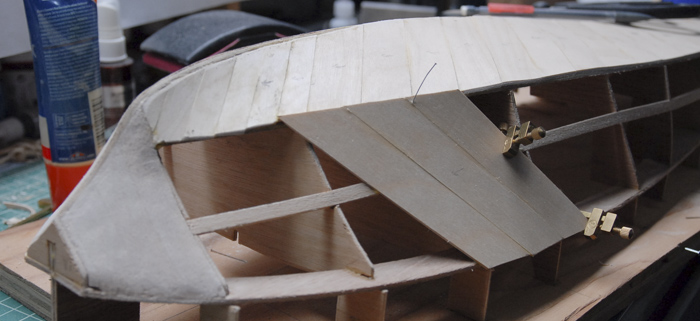

As I got closer and closer to the nose of the boat, the angle between the bottom planks and the chine (frame piece that is the line between the sides and bottom) became shallower and the area of contact between the two got smaller. What I decided to do was add a few strips of basswood, trimmed to the correct angle, in order to give more contact area. Below you can see those strips in place.

A different angle on the same strips. You can see that the left side is untrimmed, while the right side is trimmed to the angle of the strips of plywood.

Below you can see the entire bottom of the boat with under-planking on it. The top edge in this photo has been sanded even with the angle of the side, while the bottom edge still looks ragged because it has not yet been sanded smooth.

The planking of the sides was very similar. I did attempt to use straight sewing pins as temporary nails. This worked some times and other times just resulted in lots of bent pins and plenty of cursing.

Using thinner strips of plywood near the front. The thinner strips are easier to bend and can therefore be formed to the sharper curves near the bow.

With the under-planking complete, the whole hull got a first pass of sanding.

In a few places, a plank or two ended up lower than I would like. In the case below, I added another bit of strip on top and then sanded it flush to the surrounding planks.

After that first pass of sanding, I put a thin layer of wood filler over most of the hull. This filled in gaps, leveled out the surface and gave me something to sand down in order to get things nice and smooth before the top plank layer.

Below you can see the filled and sanded result, all ready for the mahogany plank layer.

That seems like a good place to stop for this post. The mahogany planking is nearly done, so look for that in a forthcoming blog post!

Thanks for reading!

With a length of 27 inches, it’s a fairly large scale project (at least for me and my limited building space).

Like most kits of this type, it comes as a number of sheets of pre-cut parts, some strips of thin plywood, a bunch of strips of mahogany and bass wood, and some cast metal parts.

The instructions had me start by marking rib positions on a building board (spare plywood in this case) and then assembling and gluing the frame to the board.

That was followed by adding a few stringers and the keel boards on the bottom of the boat.

Because of the rapid change in shape between the first rib and the nose of the boat, the front is shaped from balsa. The kit came with a sheet of half-inch-thick balsa that was cut into triangles and glued in place. Below you can see the rough blocks glued in place. I had to use a little bit of spare balsa that I had laying around in order to fill the space all of the way (those thin sheets right at the front).

Below you can see the rough shaping. This was done using first a jewelers saw to cut off big chunks of the wood, then a sanding drum on a Dremel for fast shaping and then finally some 150 grit sandpaper for finer shaping.

Next up was the under-planking. This consisted of 1/16 inch thick plywood strips that are laid diagonally on the bottom and sides of the hull. The instructions said to use a thick cyanoacrylate (super glue), but I found that when the strips needed to be bent a bit, the glue tended to not have the strength to hold the strips in place. I believe that this was mostly because there were fairly small areas in which the strips contacted the frame. I had actually started the planking and then found that I had started laying the planks going the wrong direction (dark spots in photo below was the glue that held them in place). When I discovered this, I tried to take those planks off and discovered that they came off so easily that I lost all confidence in the CA method.

I decided instead to try good ol’ yellow carpenter’s glue. This required that the strips be clamped in place while the glue dried. Once dried, though, the glue was strong and the connection between the strips and frame was solid. I ended up going with this technique for all of the under-planking. Below you can see the transom in place as well as the first few planks.

Below you can see some of the clamping and weighting I needed to do in order to hold planks in place while the glue dried. Those angle blocks weigh 3lbs each, and were providing a great deal of pressure on those planks.

A closer view of the same setup.

As I got closer and closer to the nose of the boat, the angle between the bottom planks and the chine (frame piece that is the line between the sides and bottom) became shallower and the area of contact between the two got smaller. What I decided to do was add a few strips of basswood, trimmed to the correct angle, in order to give more contact area. Below you can see those strips in place.

A different angle on the same strips. You can see that the left side is untrimmed, while the right side is trimmed to the angle of the strips of plywood.

Below you can see the entire bottom of the boat with under-planking on it. The top edge in this photo has been sanded even with the angle of the side, while the bottom edge still looks ragged because it has not yet been sanded smooth.

The planking of the sides was very similar. I did attempt to use straight sewing pins as temporary nails. This worked some times and other times just resulted in lots of bent pins and plenty of cursing.

Using thinner strips of plywood near the front. The thinner strips are easier to bend and can therefore be formed to the sharper curves near the bow.

With the under-planking complete, the whole hull got a first pass of sanding.

In a few places, a plank or two ended up lower than I would like. In the case below, I added another bit of strip on top and then sanded it flush to the surrounding planks.

After that first pass of sanding, I put a thin layer of wood filler over most of the hull. This filled in gaps, leveled out the surface and gave me something to sand down in order to get things nice and smooth before the top plank layer.

Below you can see the filled and sanded result, all ready for the mahogany plank layer.

That seems like a good place to stop for this post. The mahogany planking is nearly done, so look for that in a forthcoming blog post!

Thanks for reading!

Armed Virginia Sloop - And That's That

06 - December - 2009 - 20:21

After roughly ten months of work, cutting, sanding, gluing, painting, and tying, I think this one is finally done.

The past few weeks have mostly just been spent finishing the rigging. The final few steps were to add the anchors and clean up many of the tied-off strings. The swivel guns were finally glued in place and the thick anchor rope was formed into a coil on deck.

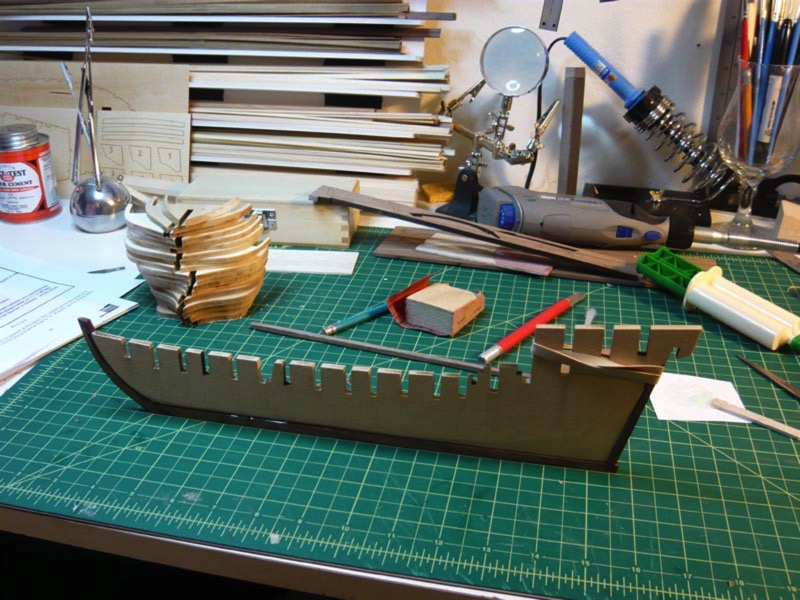

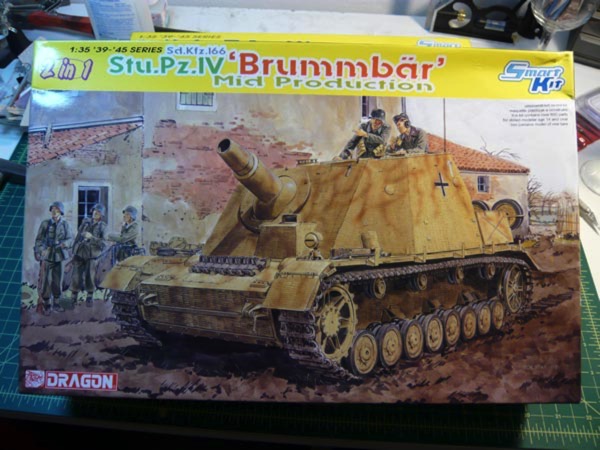

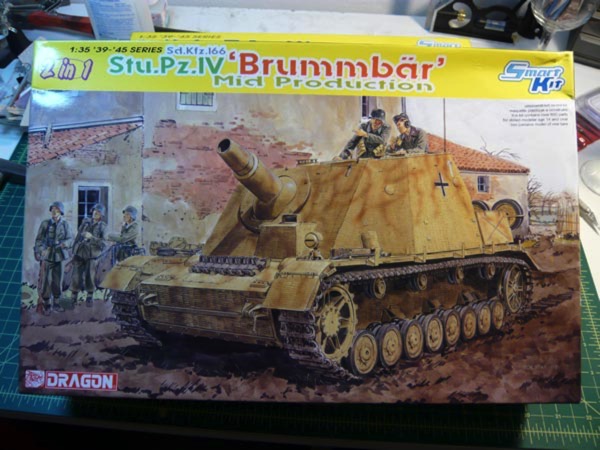

Overall this has been a very rewarding project, and I've learned an enormous amount about both working with wood on a small scale and about sailing ships themselves. But now I'm definitely ready for some non-wood projects! I've got a bit of a stockpile of plastic kits that I've built up over the past year, so keep an eye out for future updates on those.

Now, for some photos:

The past few weeks have mostly just been spent finishing the rigging. The final few steps were to add the anchors and clean up many of the tied-off strings. The swivel guns were finally glued in place and the thick anchor rope was formed into a coil on deck.

Overall this has been a very rewarding project, and I've learned an enormous amount about both working with wood on a small scale and about sailing ships themselves. But now I'm definitely ready for some non-wood projects! I've got a bit of a stockpile of plastic kits that I've built up over the past year, so keep an eye out for future updates on those.

Now, for some photos:

AVS - Rigging Update

01 - November - 2009 - 20:21

Just a quick update on my progress so far. Not a whole lot has changed since the last post. I've been fairly busy, but managed to get some more strings tied to the ship. Disclaimer: I left my camera at work on Friday, so these photos are just taken with my phone, and not touched by Photoshop, so they aren't quite as clean.

Anyway, I'm pretty much really all done with the standing rigging (with the exception of the ratlines on the shrouds, which I'll add later). Now, I'm mostly adding the lines that would run the sails up and down. I've also found that careful application of a lighter to the strings, since they are synthetic, tightens them up nicely once everything is all tied and glued.

With that, here are a few photos of the new bits:

Anyway, I'm pretty much really all done with the standing rigging (with the exception of the ratlines on the shrouds, which I'll add later). Now, I'm mostly adding the lines that would run the sails up and down. I've also found that careful application of a lighter to the strings, since they are synthetic, tightens them up nicely once everything is all tied and glued.

With that, here are a few photos of the new bits:

Armed Virginia Sloop - Masts and Rigging

25 - October - 2009 - 19:40

Finally, a long overdue update on the ship. I moved on from the bowsprit and formed the main mast, the topmast, the booms, and the yards. I settled on a technique for thinning the dowels that seemed to work pretty well: Since I didn't have a lathe, I put the dowels into my electric drill (being careful not to put them in TOO tight, since that leaves dents in the wood), and then set the drill up to the highest speed and just held sandpaper against it. This would be fairly painful using my bare hands, but I happened to have some of those silicon oven mitts, which let you hold very hot things (I had gotten them for smoking ribs). So, using the gloves, and holding 150 grit sandpaper against the spinning dowels, they were fairly quickly down to the proper diameter and taper.

After that, it was just a matter of building the trestle tree (where the main mast meets the top mast) and adding various extra bits and nubs to the yards and masts.

Below you can see the bases of the booms, with card stock wrapped around, painted and then with polyurethane on it, to simulate the iron bands that were on the real ships. You can also see the sail hoop things on the mast. Since my ship won't have sails on it, they just sit there on the mast. I took this opportunity to try out "Black It" metal blackening solution, which is supposed to chemically blacken various metals. In my case it really just turned them sort of rust colored. Although, since that looks fairly natural in the context, I decided to go with it.

With all of the various wooden parts of the rigging complete, I moved on to the strings. The practicum that I am following had me start with the bowsprit rigging and then prep almost all of the rigging on the lower mast before actually gluing the mast in place. Below you can see the completed bowsprit rigging, as well as the partially-rigged lower mast and trestle tree. On the main mast, on a few of the strings have actually been connected to the ship itself, so many of them are hanging loose in a disorderly fashion, which explains their fairly messy appearance in the photos.

Ship trivia of the day: Currently I am mostly just dealing with what is called the 'standing rigging', which are the ropes that generally do not move when the sails go up and down, but instead serve to hold the various masts, etc in place. These ropes were usually coated with tar, to waterproof them, and so, on my model, are made from the black string.

Here are a few photos of the upper rigging meeting the ship.

Finally, the ship in its current state. Standing rigging in progress, with mast and bowsprit attached. The rigging is moving along at a good pace so far, so I am hoping to increase the frequency of my updates on it :)

After that, it was just a matter of building the trestle tree (where the main mast meets the top mast) and adding various extra bits and nubs to the yards and masts.

Below you can see the bases of the booms, with card stock wrapped around, painted and then with polyurethane on it, to simulate the iron bands that were on the real ships. You can also see the sail hoop things on the mast. Since my ship won't have sails on it, they just sit there on the mast. I took this opportunity to try out "Black It" metal blackening solution, which is supposed to chemically blacken various metals. In my case it really just turned them sort of rust colored. Although, since that looks fairly natural in the context, I decided to go with it.

With all of the various wooden parts of the rigging complete, I moved on to the strings. The practicum that I am following had me start with the bowsprit rigging and then prep almost all of the rigging on the lower mast before actually gluing the mast in place. Below you can see the completed bowsprit rigging, as well as the partially-rigged lower mast and trestle tree. On the main mast, on a few of the strings have actually been connected to the ship itself, so many of them are hanging loose in a disorderly fashion, which explains their fairly messy appearance in the photos.

Ship trivia of the day: Currently I am mostly just dealing with what is called the 'standing rigging', which are the ropes that generally do not move when the sails go up and down, but instead serve to hold the various masts, etc in place. These ropes were usually coated with tar, to waterproof them, and so, on my model, are made from the black string.

Here are a few photos of the upper rigging meeting the ship.

Finally, the ship in its current state. Standing rigging in progress, with mast and bowsprit attached. The rigging is moving along at a good pace so far, so I am hoping to increase the frequency of my updates on it :)

Armed Virginia Sloop - Odds and Ends

27 - September - 2009 - 20:43

I was off on vacation for a week, so the updates lagged a bit behind. But, now I am back and have had a little time to work on the ship.

I don't really have any great insights to share this time around, so just a quick post to update my progress and show a few photos of where I am at the moment.

First off, I had to wrap up a few remaining deck fixtures. This included the little stairs to the top deck/roof, lots of little cleats, attaching all the bases for the swivel cannons, the swivel cannons themselves, various holes being drilled for future attachments, etc. Also, I added the channels, chainplates and deadeyes (those wings and round things sticking off the sides of the ship) in preparation for adding the masts and rigging.

Next, since the ship is mostly just getting rigging stuff added from this point on, I built the real base, which is a model of the launching ways. This was built all from 1/4" basswood stock, cut to size, stained, and then glued into place. There was a little bit of fiddly work, getting all the proper angles cut into the upright support parts, but nothing too tough :)

Finally, I've started work on the masts. First up was the bowsprit (big one) and the jibboom (little one). The bowsprit was fashioned from a 3/8" dowel which has to be slimmed down by using a combination of sanding drums in a dremel, and sanding the dowel while it is spinning in a drill. This was mostly quite a bit of experimentation, and I can't say that either method really worked all that well, but it got the job done. Anyhow, that's where I am now, with the bowsprit temporarily installed. Next up are various little fittings on the bowsprit, and then moving on to the main mast.

I don't really have any great insights to share this time around, so just a quick post to update my progress and show a few photos of where I am at the moment.

First off, I had to wrap up a few remaining deck fixtures. This included the little stairs to the top deck/roof, lots of little cleats, attaching all the bases for the swivel cannons, the swivel cannons themselves, various holes being drilled for future attachments, etc. Also, I added the channels, chainplates and deadeyes (those wings and round things sticking off the sides of the ship) in preparation for adding the masts and rigging.

Next, since the ship is mostly just getting rigging stuff added from this point on, I built the real base, which is a model of the launching ways. This was built all from 1/4" basswood stock, cut to size, stained, and then glued into place. There was a little bit of fiddly work, getting all the proper angles cut into the upright support parts, but nothing too tough :)

Finally, I've started work on the masts. First up was the bowsprit (big one) and the jibboom (little one). The bowsprit was fashioned from a 3/8" dowel which has to be slimmed down by using a combination of sanding drums in a dremel, and sanding the dowel while it is spinning in a drill. This was mostly quite a bit of experimentation, and I can't say that either method really worked all that well, but it got the job done. Anyhow, that's where I am now, with the bowsprit temporarily installed. Next up are various little fittings on the bowsprit, and then moving on to the main mast.

Armed Virginia Sloop - Getting Crowded On Deck

07 - September - 2009 - 22:00

Another small update today. This mostly consists of various deck furniture and fittings. First up are the boom crutches:

(very exciting, I know)

In the next photo, you can see the smokestack for the galley, the riding bitt (little rope rack thing in the left-middle, there) and the catheads (little arms that stick off the front. No cats harmed in the making of this model).

Then, the more complicated stuff: The ships wheel, the water pumps and the binnacle. The ships wheel and pumps seems fairly self evident, but if you are like me, you probably thought something like, "Binnacle? Is that like a barnacle? Perhaps the pinnacle of all barnacles, a sort of super-barnacle?" Turns out a binnacle is that little cabinet thing in front of the ships wheel that houses, among other things, the ships compass, which is supposed to be behind the little window.

The only noteworthy thing here is that I tried out using my drill as a makeshift lathe in order to turn a dowel into a pulley for the ships wheel (left side, where the string loops around). It seems to have worked decently, but I wouldn't recommend it for precision work.

That's where I am now. More updates to follow as I progress!

(very exciting, I know)

In the next photo, you can see the smokestack for the galley, the riding bitt (little rope rack thing in the left-middle, there) and the catheads (little arms that stick off the front. No cats harmed in the making of this model).

Then, the more complicated stuff: The ships wheel, the water pumps and the binnacle. The ships wheel and pumps seems fairly self evident, but if you are like me, you probably thought something like, "Binnacle? Is that like a barnacle? Perhaps the pinnacle of all barnacles, a sort of super-barnacle?" Turns out a binnacle is that little cabinet thing in front of the ships wheel that houses, among other things, the ships compass, which is supposed to be behind the little window.

The only noteworthy thing here is that I tried out using my drill as a makeshift lathe in order to turn a dowel into a pulley for the ships wheel (left side, where the string loops around). It seems to have worked decently, but I wouldn't recommend it for precision work.

That's where I am now. More updates to follow as I progress!

Armed Virginia Sloop - Now Armed!

02 - September - 2009 - 21:48

First off, I've gotten the rudder attached. This wasn't too tough, but I thought that I would share a little trick I used. The course I am following didn't make any mention of the little bolt heads that secure the straps to the rudder and to the ship. The plans make a brief mention of using cut off bits of wire for these bolt heads. I figured that even if I managed to cut off that small of a piece of wire without it flying across the room and disappearing, then trying to get that tiny bit super glued to the rudder was going to be practically impossible. So, instead, I borrowed a jar of acrylic medium (thick), and dipped a T pin into it and dabbed little bits of the gel onto the metal straps. This left nice little dots on there, which were just the right size. Once dry, a little brush with fine sandpaper to take the points off the dabs, and then I painted over both the metal strap and the gel and it all turned out pretty well, if I may say so.

Once the rudder was all done, I set about rigging, and attaching the cannons to the ship. The rigging was extra fiddly, as it required some very small knots be tied and some fairly springy rope be coiled. I am now proud to say that I can precisely tie an hangman's knot that is only a few millimeters long. Should anyone need to hang any traitorous insects, I can be of assistance.

This step had one goof and one trick.

The goof: turns out I rigged the cannons backwards when it came to the little block-and-tackle things on the sides. The blocks with two holes were supposed to be towards the outside of the ship, resulting in the rope exiting the rigging near the railing of the ship and making much more sense, if you think about how one would haul on the rope to run the cannon out. But since I didn't discover this until I had already rigged all the cannons, I decided it wasn't too big a deal.

The trick: The course I am following suggested forming the rope coils (on the deck next to each cannon) by soaking the string in a mixture of Elmer's glue and water and then then using a wet paintbrush to form the ring of rope. I think my string may have been a different type (polyester instead of cotton), since it didn't really seem to soak up the glue mixture and become more pliable. Instead it mostly just spread glue all around the deck of the ship as I tried to get it to stay in place. Eventually, I gave up on that method and decided to instead form the coils by wrapping the string around the handle of a paintbrush (carefully overlapping, so that it built up some thickness and held itself in place) and the putting a dab of superglue (fast) on at the end to hold the coil together. Then, before the glue complete hardened, I slipped the coil off the brush handle and glued it down to the deck with another dab of superglue (slow). This seemed to do the trick, and aside from gluing my fingers together and to the rope a few times, it turned out pretty well.

That's it for now. Next up are a few more pieces of random deck furniture, the little railing guns and various rigging fittings.

Once the rudder was all done, I set about rigging, and attaching the cannons to the ship. The rigging was extra fiddly, as it required some very small knots be tied and some fairly springy rope be coiled. I am now proud to say that I can precisely tie an hangman's knot that is only a few millimeters long. Should anyone need to hang any traitorous insects, I can be of assistance.

This step had one goof and one trick.

The goof: turns out I rigged the cannons backwards when it came to the little block-and-tackle things on the sides. The blocks with two holes were supposed to be towards the outside of the ship, resulting in the rope exiting the rigging near the railing of the ship and making much more sense, if you think about how one would haul on the rope to run the cannon out. But since I didn't discover this until I had already rigged all the cannons, I decided it wasn't too big a deal.

The trick: The course I am following suggested forming the rope coils (on the deck next to each cannon) by soaking the string in a mixture of Elmer's glue and water and then then using a wet paintbrush to form the ring of rope. I think my string may have been a different type (polyester instead of cotton), since it didn't really seem to soak up the glue mixture and become more pliable. Instead it mostly just spread glue all around the deck of the ship as I tried to get it to stay in place. Eventually, I gave up on that method and decided to instead form the coils by wrapping the string around the handle of a paintbrush (carefully overlapping, so that it built up some thickness and held itself in place) and the putting a dab of superglue (fast) on at the end to hold the coil together. Then, before the glue complete hardened, I slipped the coil off the brush handle and glued it down to the deck with another dab of superglue (slow). This seemed to do the trick, and aside from gluing my fingers together and to the rope a few times, it turned out pretty well.

That's it for now. Next up are a few more pieces of random deck furniture, the little railing guns and various rigging fittings.

Armed Virginia Sloop - quick update

16 - August - 2009 - 21:43

After a few weeks of turmoil, I'm beginning to get a bit of time here and there to work on the models again. This update shows the completed (sorta) cannons and the beginnings of the rudder. I added the 'sorta' to the cannons, as they still have a good deal of rigging work that will be done later in order to actually attach them to the ship itself. The rudder I just started today and should go pretty quick, since it is just a bit of simple sanding, carving and then cutting some bits of metal.

Armed Virginia Sloop - All Decking Complete

26 - July - 2009 - 20:44

Just a quick update to show the completed decking. At long last all the of frame and structure of the ship is covered. The next step is to start building the cannons, but I've got lots going on over the next week or two, so there may not be a worthwhile update here for a few weeks :)

Armed Virginia Sloop - Decking

19 - July - 2009 - 19:40

Just a few images here of the in-progress deck planking. The main decking is done, and is soon to be followed by the mid deck planking. The black lines between planks here are meant to simulate the tar that was used on ships to waterproof the deck. In my model I just used a sharpie to color the edges of the planks before assembling them :) The various deck items from the previous post are shown below, although they are not actually glued into place yet.

Armed Virginia Sloop - Deck Objects

05 - July - 2009 - 20:45

A few days of cutting, sanding and gluing has brought forth an assortment of tiny little items:

There is a penny in the photo for size comparison, but needless to say, I had to learn to use two pairs of tweezers simultaneously in combination with a magnifying lamp. The grating on the smallest bit was assembled from some machine-cut comb-looking parts, so wasn't quite as tricky as it may look. I'm pretty happy with how the various brass bits turned out, although I found it quite difficult to satisfactorily file the ends of the brass wire that was used to simulate hinge pins. The files that I have are simply too coarse to smooth the ends of the wire, which get sort of smashed down by the wire cutters.

These are all of the deck buildings, though, so next step is main deck planking, and then cannons!

There is a penny in the photo for size comparison, but needless to say, I had to learn to use two pairs of tweezers simultaneously in combination with a magnifying lamp. The grating on the smallest bit was assembled from some machine-cut comb-looking parts, so wasn't quite as tricky as it may look. I'm pretty happy with how the various brass bits turned out, although I found it quite difficult to satisfactorily file the ends of the brass wire that was used to simulate hinge pins. The files that I have are simply too coarse to smooth the ends of the wire, which get sort of smashed down by the wire cutters.

These are all of the deck buildings, though, so next step is main deck planking, and then cannons!

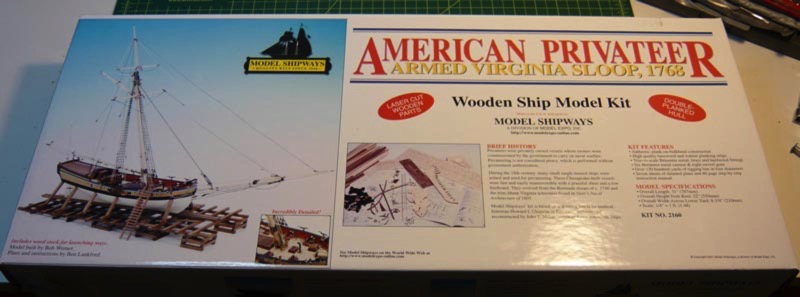

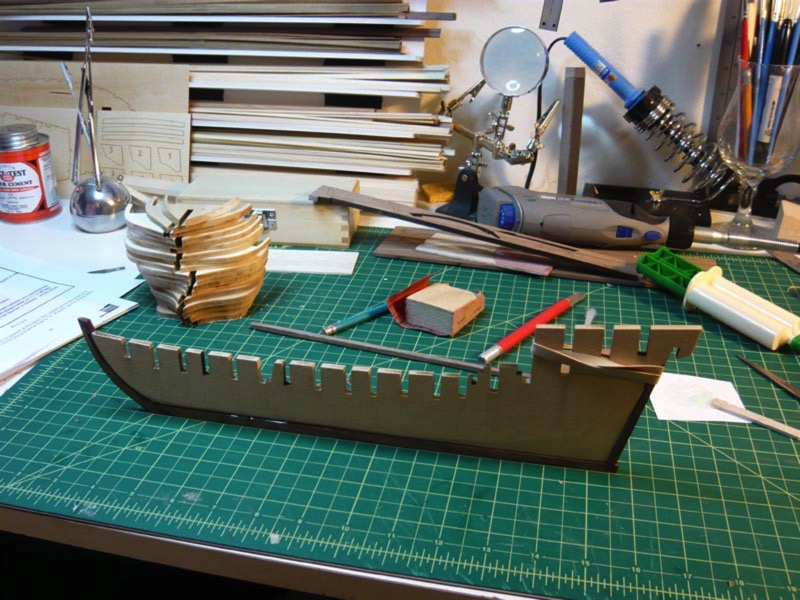

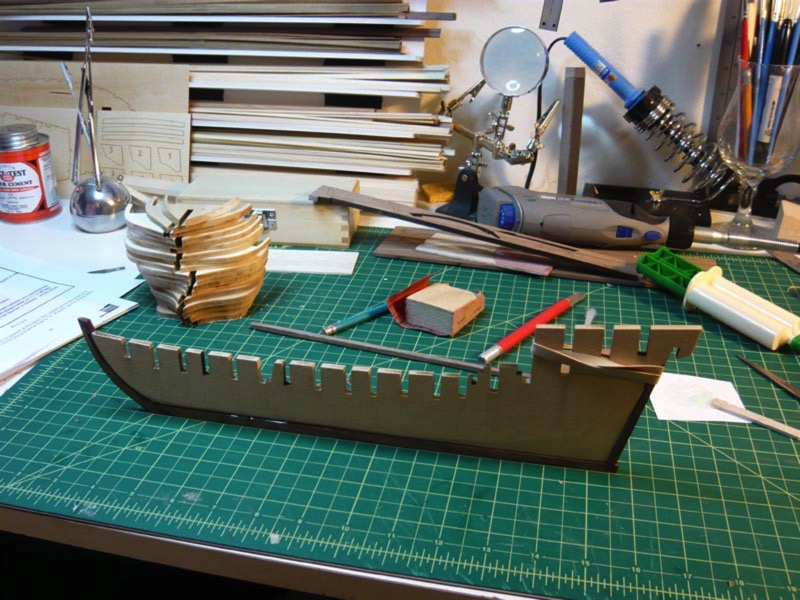

Armed Virginia Sloop - Planking Complete

03 - July - 2009 - 16:54

I've wrapped up the hull planking at long last. All in all, it was not too difficult overall, once I understood what the general goals were. It was a bit tedious, after a while, but I think the end result is very pleasing. Here are a few images of the unsanded and unfinished planking. In the second image, you can see where I goofed the planking pattern a bit.

Next I spent some time sanding the planking all smooth, starting with 150-grit sandpaper and then moving to 280 and then 320. Then, a coat of sanding sealer, some more sanding, and finally three coats of satin polyurethane.

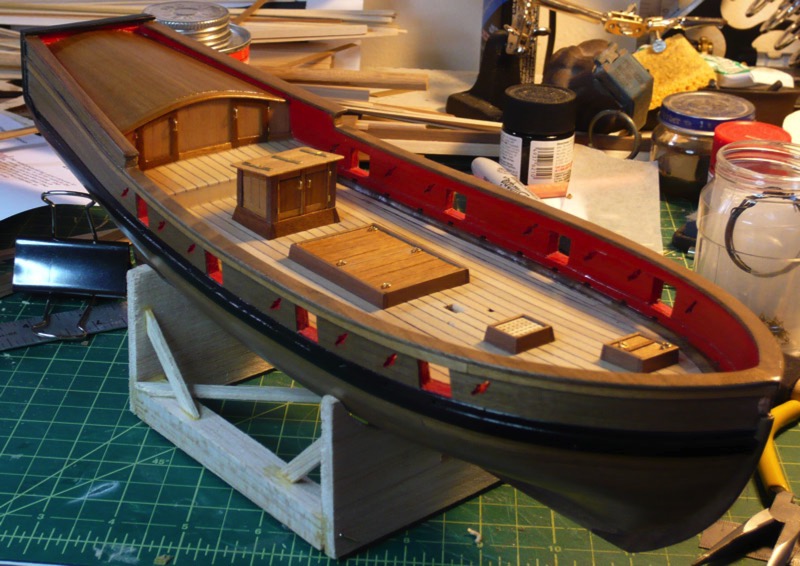

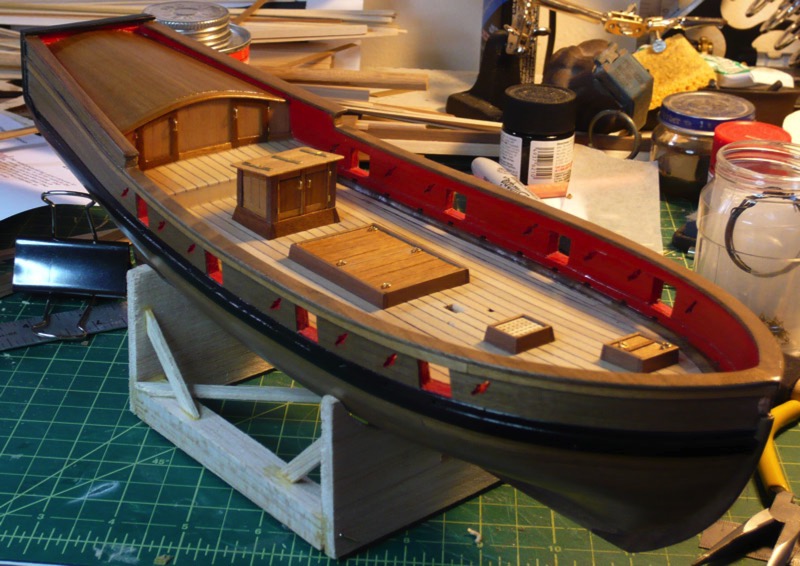

Today, I spent time drilling and cutting and sanding the oar sweeps (diagonal holes in the sides). These were a little tricky, since the center hole is only 3/32" and I had to resort to the tiny bits (#62, I think) to drill through for the diagonal parts. Once the holes were drilled, I cut in between the holes with a tiny saw, and then made a thin sanding strip with some planking glued to sandpaper. I used that little sander to even out the interior of the holes. Then I painted the interior of each hole red, and then put polyurethane over everything that got painted or sanded, in order to have a nice uniform finish over everything. Finally, I decided to built a quick little working stand for the ship, since most of the work from this point on it on the deck. I just cut up some balsa that I had laying about and built a little stand, using the dremel to quickly get the stand to conform to the shape of the hull. There are some little felt circles in between the stand and hull, to avoid scrapes over time.

The kit comes with wood to build a stand, but since that wood is basswood, I was a little wary of building that stand now, since I think the basswood would get pretty beat up over time. I figure that this little balsa stand should do the trick for the time being and I don't have to worry too much about it getting broken. Anyhow, this is where the model stands at the moment:

Next I spent some time sanding the planking all smooth, starting with 150-grit sandpaper and then moving to 280 and then 320. Then, a coat of sanding sealer, some more sanding, and finally three coats of satin polyurethane.

Today, I spent time drilling and cutting and sanding the oar sweeps (diagonal holes in the sides). These were a little tricky, since the center hole is only 3/32" and I had to resort to the tiny bits (#62, I think) to drill through for the diagonal parts. Once the holes were drilled, I cut in between the holes with a tiny saw, and then made a thin sanding strip with some planking glued to sandpaper. I used that little sander to even out the interior of the holes. Then I painted the interior of each hole red, and then put polyurethane over everything that got painted or sanded, in order to have a nice uniform finish over everything. Finally, I decided to built a quick little working stand for the ship, since most of the work from this point on it on the deck. I just cut up some balsa that I had laying about and built a little stand, using the dremel to quickly get the stand to conform to the shape of the hull. There are some little felt circles in between the stand and hull, to avoid scrapes over time.

The kit comes with wood to build a stand, but since that wood is basswood, I was a little wary of building that stand now, since I think the basswood would get pretty beat up over time. I figure that this little balsa stand should do the trick for the time being and I don't have to worry too much about it getting broken. Anyhow, this is where the model stands at the moment:

Armed Virginia Sloop - continued

28 - June - 2009 - 21:53

I've been steadily plugging away on this model, mostly on planking-related tasks. I decided to do a little bit of painting, somewhat for accent/contrast, and somewhat to cover areas that would look bad if not painted (inside the gunports).

Here you can see the insides of the railing things painted the appropriate red color. I discovered, once I had the sides built up and the railings installed, that the back deck sides on my model were a bit taller than they are supposed to be. This meant that the sides up there, on my model, were only as thick as the outside basswood planking and looked pretty weird. So I spent a bit of time adding a few layers of wood to give those back walls thickness. It seems to have turned out okay, and I'm hoping it won't cause any issues later on in the build.

Once that was complete, I moved on to installing some of the main thicker planks on the upper outside of the hull and then adding the thin walnut finish planking to the upper areas.

From that point it was just a matter of planking the rest of the lower hull. It took me a little while to get the hang of how things go, but this task isn't too tough. It does get a bit tedious though, since it is really just a great deal of measuring and trimming plank after plank. Below you can see some of the masking tape guidelines that I used in order to help me control the flow of the planks around the hull.

I found that once I masked off a new line (based off of plank width), I could then go back and eyeball rough divisions of the intermediate space. So, for example, if the space between the tape and the finished planks required five full-width planks to cover it at the widest spot, then I would then move along the length of the ship and make marks that divided the space into five sections. If I did this every two inches or so, I found that I could then simply lay down an uncut 4" plank, see where it needed to be width-wise and then trim as needed. Then it was just a simple matter of cutting, gluing and, in some cases, soaking and bending, all of the planks required to fill the space. To the right, you can see the hull, a bit further along, with the markings for the last section in place.

That said, I discovered today that I still managed to goof up the planking on one side of the hull. It's nothing too major, but my planking pattern is off on every third plank, so that instead of a nice even distribution of plank ends, they are a bit offset. Since I was already about two thirds of the way done on that side, I decided I could live with it :)

Finally, here is where I stand at the moment. One side of the hull is planked, and the other side is about two thirds of the way complete. Once I finish the other side, I'll sand it all smooth, and then hit it with some sanding sealer, and polyurethane. Once I am happy with the exterior finish, it'll be time to move on to constructing some of the deck structures. I will be quite happy to be able to take a break from planking at that point (I'll still have to plank the main deck later). Overall, I am very happy with how things are progressing, although it seems that, when I ordered this kit in the first place, I grossly underestimated the amount of time required to complete it. At this rate, I'll be lucky if I have completed the kit before a year has elapsed since the kit first came into my possession. But it is a fun project and definitely the challenge I was hoping for!

Here you can see the insides of the railing things painted the appropriate red color. I discovered, once I had the sides built up and the railings installed, that the back deck sides on my model were a bit taller than they are supposed to be. This meant that the sides up there, on my model, were only as thick as the outside basswood planking and looked pretty weird. So I spent a bit of time adding a few layers of wood to give those back walls thickness. It seems to have turned out okay, and I'm hoping it won't cause any issues later on in the build.

Once that was complete, I moved on to installing some of the main thicker planks on the upper outside of the hull and then adding the thin walnut finish planking to the upper areas.

From that point it was just a matter of planking the rest of the lower hull. It took me a little while to get the hang of how things go, but this task isn't too tough. It does get a bit tedious though, since it is really just a great deal of measuring and trimming plank after plank. Below you can see some of the masking tape guidelines that I used in order to help me control the flow of the planks around the hull.

I found that once I masked off a new line (based off of plank width), I could then go back and eyeball rough divisions of the intermediate space. So, for example, if the space between the tape and the finished planks required five full-width planks to cover it at the widest spot, then I would then move along the length of the ship and make marks that divided the space into five sections. If I did this every two inches or so, I found that I could then simply lay down an uncut 4" plank, see where it needed to be width-wise and then trim as needed. Then it was just a simple matter of cutting, gluing and, in some cases, soaking and bending, all of the planks required to fill the space. To the right, you can see the hull, a bit further along, with the markings for the last section in place.

That said, I discovered today that I still managed to goof up the planking on one side of the hull. It's nothing too major, but my planking pattern is off on every third plank, so that instead of a nice even distribution of plank ends, they are a bit offset. Since I was already about two thirds of the way done on that side, I decided I could live with it :)

Finally, here is where I stand at the moment. One side of the hull is planked, and the other side is about two thirds of the way complete. Once I finish the other side, I'll sand it all smooth, and then hit it with some sanding sealer, and polyurethane. Once I am happy with the exterior finish, it'll be time to move on to constructing some of the deck structures. I will be quite happy to be able to take a break from planking at that point (I'll still have to plank the main deck later). Overall, I am very happy with how things are progressing, although it seems that, when I ordered this kit in the first place, I grossly underestimated the amount of time required to complete it. At this rate, I'll be lucky if I have completed the kit before a year has elapsed since the kit first came into my possession. But it is a fun project and definitely the challenge I was hoping for!

Armed Virginia Sloop, pt 6

14 - June - 2009 - 20:18

Construction Continues.... The past few weeks have been super busy, and I've only just this weekend been able to devote some time to working on the ship.

Here you can see the ship all clamped up as I was gluing in the little basswood blocks where the sweep ports (oar-holes) go. Once that was all done, I found that I had to shim some of the ribs in order to get a uniform thickness everywhere. So, I spent some time shimming and trimming and sanding and cutting, and once satisfied, I was able to put the walnut planking on the inside.

Here you can see the ship all clamped up as I was gluing in the little basswood blocks where the sweep ports (oar-holes) go. Once that was all done, I found that I had to shim some of the ribs in order to get a uniform thickness everywhere. So, I spent some time shimming and trimming and sanding and cutting, and once satisfied, I was able to put the walnut planking on the inside.

AVS Update (finally)

24 - May - 2009 - 22:00

So, at long last, I am finally updating the blog on the progress of the Armed Virginia Sloop.

I have been make slow but steady progress on the ship over the past two months, and more recently I've tried to increase my pace a little bit, as I was getting discouraged by the lack of visible progress. Currently, I have finished the first layer of exterior planking on the hull and am just beginning the walnut layer on both the inside of the rails and on the outside. Here are some images from the past two months and a little bit about them:

This first one shows the installation of the waterways, which I had been hung up on for a while. These were fairly thick, laser-cut, walnut parts that required a pretty big bevel along their length. Since I thought this was going to be tricky to get right, I had stalled for a while on it (plus I was pretty busy in outside life as well). But, once I got down to it, it turned out to not be that big a deal and I only cut myself a few times with the x-acto knife ;)

This next image shows the rear cabiny thing pretty much all done. This was actually a multi-step process, consisting of first planking in basswood. This first step was my introduction to planking with soaked wood (for added flexibility), which turned out to be quite handy. Once the area was planked with the basswood, it got a good sanding, and then the window frames were installed. I had some left over window plastic from the last boat I built (the Chris Craft at the bottom), so I cut some small squares from that and glued those to the backs of all the window frames with some Testors clear parts cement. Next, the area was given a final planking with the walnut layer, which required some delicate cutting and fitting around the frame areas. To finish it off, the surface was sanded smooth and given a light coat of polyurethane to seal it up a bit.

Here is another view of the cabin area. You can also see the first few planks going on the side. This mostly involved a process of roughly measuring the planks, then soaking them in water for a bit, then attaching them with super glue. Once the wood had dried out a bit, things are trimmed and sanded to fit nicely.

There is a bit of a trick to this whole stern area, as many of the bits sort of rely on one another for positioning. The course that I am following (see link in sidebar) does a good job of differing from the kits instructions in order to make these interrelationships obvious. As a result, it sort of skips back and forth for a bit, adding a few planks, then some trim pieces, then more planks, etc.

Here is an image of the walnut trim corner pieces in place. These interact with the installed walnut planking, as well as the side planks in the way that it fits together. This step also required a bit of muscle (delicately) to bend my top rear planks out a bit. They had ended up curling in a bit, so that when i installed the straight trim pieces, they did not line up properly. With a little bit of super glue, some delicate but firm pressure, and some patience, I managed to bend the rear surface out a bit to align with the trim. This looked much better and generally filled life with happiness ;)

Skipping ahead a few weeks, the planking is well underway. This mostly involved steps of pinning, drawing guide lines along the planks, unpinning, careful cutting, soaking and then finally gluing in place, with a bit of trimming at one end for a proper fit. Not too tough, really, but pretty slow going. I think I averaged two to four planks on evenings that I was able to work on the ship. The image to the left is probably three to four weeks of slow work. Once I got this far though, I got excited about being almost done this stage, and pushed ahead a bit quicker. As a result, I am now all done with the basswood planking!

As you can see, in this image, The planking is complete and I've spent a bit of time sanding the whole hull and filling in a few gaps with green putty. Overall, I'm quite pleased with how it turned out

for being my first ship. There are a few areas that could be better (hence the need for the filler), but really nothing that is too bad. It was a bit tricky getting the planks to bend at the stern, as the planks were pretty wide (1/4") and the required bend was pretty extreme. But once all was sanded and filled, it seemed to work out just fine.

Next up is to begin the walnut planking on the interior of the railing. I believe this also involves a bit of cutting and fitting to a few pieces, but didn't look too complicated.

I'm hoping to be a little better about updates from here on, so keep an eye out for small posts as I progress!

Also, on a side note, be sure to go see Pixar's 'Up' this coming week, when it comes out! It's a great film!

I have been make slow but steady progress on the ship over the past two months, and more recently I've tried to increase my pace a little bit, as I was getting discouraged by the lack of visible progress. Currently, I have finished the first layer of exterior planking on the hull and am just beginning the walnut layer on both the inside of the rails and on the outside. Here are some images from the past two months and a little bit about them:

This first one shows the installation of the waterways, which I had been hung up on for a while. These were fairly thick, laser-cut, walnut parts that required a pretty big bevel along their length. Since I thought this was going to be tricky to get right, I had stalled for a while on it (plus I was pretty busy in outside life as well). But, once I got down to it, it turned out to not be that big a deal and I only cut myself a few times with the x-acto knife ;)

This next image shows the rear cabiny thing pretty much all done. This was actually a multi-step process, consisting of first planking in basswood. This first step was my introduction to planking with soaked wood (for added flexibility), which turned out to be quite handy. Once the area was planked with the basswood, it got a good sanding, and then the window frames were installed. I had some left over window plastic from the last boat I built (the Chris Craft at the bottom), so I cut some small squares from that and glued those to the backs of all the window frames with some Testors clear parts cement. Next, the area was given a final planking with the walnut layer, which required some delicate cutting and fitting around the frame areas. To finish it off, the surface was sanded smooth and given a light coat of polyurethane to seal it up a bit.

Here is another view of the cabin area. You can also see the first few planks going on the side. This mostly involved a process of roughly measuring the planks, then soaking them in water for a bit, then attaching them with super glue. Once the wood had dried out a bit, things are trimmed and sanded to fit nicely.

There is a bit of a trick to this whole stern area, as many of the bits sort of rely on one another for positioning. The course that I am following (see link in sidebar) does a good job of differing from the kits instructions in order to make these interrelationships obvious. As a result, it sort of skips back and forth for a bit, adding a few planks, then some trim pieces, then more planks, etc.

Here is an image of the walnut trim corner pieces in place. These interact with the installed walnut planking, as well as the side planks in the way that it fits together. This step also required a bit of muscle (delicately) to bend my top rear planks out a bit. They had ended up curling in a bit, so that when i installed the straight trim pieces, they did not line up properly. With a little bit of super glue, some delicate but firm pressure, and some patience, I managed to bend the rear surface out a bit to align with the trim. This looked much better and generally filled life with happiness ;)

Skipping ahead a few weeks, the planking is well underway. This mostly involved steps of pinning, drawing guide lines along the planks, unpinning, careful cutting, soaking and then finally gluing in place, with a bit of trimming at one end for a proper fit. Not too tough, really, but pretty slow going. I think I averaged two to four planks on evenings that I was able to work on the ship. The image to the left is probably three to four weeks of slow work. Once I got this far though, I got excited about being almost done this stage, and pushed ahead a bit quicker. As a result, I am now all done with the basswood planking!

As you can see, in this image, The planking is complete and I've spent a bit of time sanding the whole hull and filling in a few gaps with green putty. Overall, I'm quite pleased with how it turned out

for being my first ship. There are a few areas that could be better (hence the need for the filler), but really nothing that is too bad. It was a bit tricky getting the planks to bend at the stern, as the planks were pretty wide (1/4") and the required bend was pretty extreme. But once all was sanded and filled, it seemed to work out just fine.

Next up is to begin the walnut planking on the interior of the railing. I believe this also involves a bit of cutting and fitting to a few pieces, but didn't look too complicated.

I'm hoping to be a little better about updates from here on, so keep an eye out for small posts as I progress!

Also, on a side note, be sure to go see Pixar's 'Up' this coming week, when it comes out! It's a great film!

Armed Virginia Sloop, pt4

24 - March - 2009 - 21:38

I haven't had much time recently to work on the ship, but I have managed to get the rear structure built and the front filler pieces cut and fit and sanded. Both ends took a good deal of shaping and sanding, and therefore took a bit longer than I was expecting.

I highly recommend getting a Dustbuster for your work area, if you don't already have one. I have found that having a little vacuum like that around allows me to really keep the amount of sawdust and wood shavings to a minimum. I'm hoping, in the long run, that this will save me a good deal of cleaning later. When I built the little speedboat (lower on the page), I ended up with a coating of fine sawdust all over everything in the room, which was a real task to clean up.

Here are a few photos of where I currently am. I am also goofing around with the picture layout thing. It's a bit clumsy to use.

I highly recommend getting a Dustbuster for your work area, if you don't already have one. I have found that having a little vacuum like that around allows me to really keep the amount of sawdust and wood shavings to a minimum. I'm hoping, in the long run, that this will save me a good deal of cleaning later. When I built the little speedboat (lower on the page), I ended up with a coating of fine sawdust all over everything in the room, which was a real task to clean up.

Here are a few photos of where I currently am. I am also goofing around with the picture layout thing. It's a bit clumsy to use.

Armed Virginia Sloop, pt3

15 - March - 2009 - 21:29

At long last I have an update for this build. I've managed to get most of the frame of the hull assembled. The actual assembly was pretty quick (it's easy to glue things together), but once things were assembled, there was a great deal of sanding and fitting to do to make life easier inlater steps. Apparently, this is called 'fairing' the hull. It mostly consists of taking a scrap strip of wood and laying it along the outside of the hull so that one can see which ribs stick up higher or are lower than the rest. Then one must sand down the high ribs or glue on strips of wood for the low ribs. Then there is more sanding, a bit of sneezing (turns out my nose doesn't like saw dust very much), then a bit more fitting and sanding. There is also a great deal of accidental breakage of tiny wood parts, followed by loud cursing and then some reglueing of those parts.

This is also where the course that I am following differs a bit from the instructions that come with the kit. The course had me attach the sub decking (just a thin sheet of basswood) before framing the rear cabin, in order to give strength to the whole ship. While the instructions suggested putting little support pieces between the ribs to give it strength, and doesn't have me put on the subdeck until after all the rest of the framing is done. I can appreciate that the course method saves me quite a bit of time that would have otherwise been spent cutting little blocks of wood, but I like to think I made up for it in time spent glueing pieces of that thin deck back on after I managed to break them off while working on a different part of the hull. ;-)

All in all, I think I've got the hull faired and am ready to move on to framing up the rear cabin of the ship. There is probably a better term for that part of a ship, but I can't remember it at the moment :)

Anyhoo, here are some photos of where I am now:

This is also where the course that I am following differs a bit from the instructions that come with the kit. The course had me attach the sub decking (just a thin sheet of basswood) before framing the rear cabin, in order to give strength to the whole ship. While the instructions suggested putting little support pieces between the ribs to give it strength, and doesn't have me put on the subdeck until after all the rest of the framing is done. I can appreciate that the course method saves me quite a bit of time that would have otherwise been spent cutting little blocks of wood, but I like to think I made up for it in time spent glueing pieces of that thin deck back on after I managed to break them off while working on a different part of the hull. ;-)

All in all, I think I've got the hull faired and am ready to move on to framing up the rear cabin of the ship. There is probably a better term for that part of a ship, but I can't remember it at the moment :)

Anyhoo, here are some photos of where I am now:

Armed Virginia Sloop, pt 2

03 - March - 2009 - 21:56

I've gotten a little start on the ship. Mostly some cutting, sanding and fitting. I cut out the keel, and all the bulkheads, sanded their edges, and sanded the joints a bit until they all fit together. I've also received the practicum course mentioned below, and have been reading and following that.

I did some cutting and beveling on the center keel and have just started to actually attach some pieces together. You can see below, I've glued the walnut keel pieces to the edges of the basswood center keel. Next comes more cutting and carving and fitting, as I need to be sure that the groove into which all the planking will later fit is the proper size and angle before all the bulkheads get glued in place.

On a side note, today I received the pegboard that I order a few weeks ago. So, I spent some time this evening organizing and generally pegging things up on my board. Really, the goal was just to get many of my tools up off the desk, giving me more work space.

This past weekend, I also spent a few minutes making myself a little foamcore shelf sort of thing that I could put all the plank wood on, to keep it out of the way and to keep it from getting broken. In the below photo, you can see the little shelf below the left side of the pegboard.

Next post will hopefully have the bulkheads in place, and the shape of the ship will actually be a bit more visible.

I did some cutting and beveling on the center keel and have just started to actually attach some pieces together. You can see below, I've glued the walnut keel pieces to the edges of the basswood center keel. Next comes more cutting and carving and fitting, as I need to be sure that the groove into which all the planking will later fit is the proper size and angle before all the bulkheads get glued in place.

On a side note, today I received the pegboard that I order a few weeks ago. So, I spent some time this evening organizing and generally pegging things up on my board. Really, the goal was just to get many of my tools up off the desk, giving me more work space.

This past weekend, I also spent a few minutes making myself a little foamcore shelf sort of thing that I could put all the plank wood on, to keep it out of the way and to keep it from getting broken. In the below photo, you can see the little shelf below the left side of the pegboard.

Next post will hopefully have the bulkheads in place, and the shape of the ship will actually be a bit more visible.

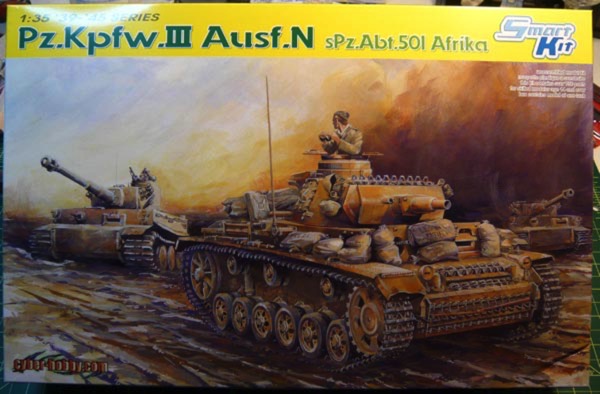

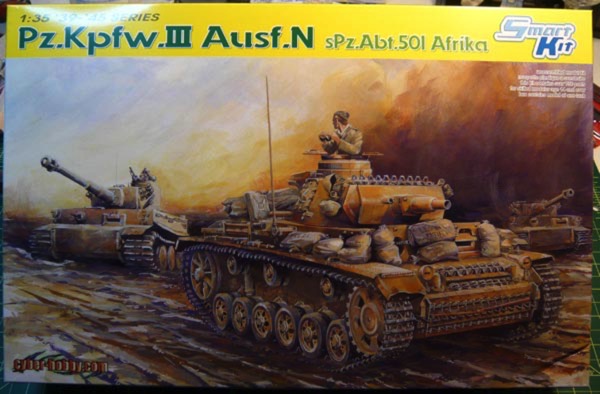

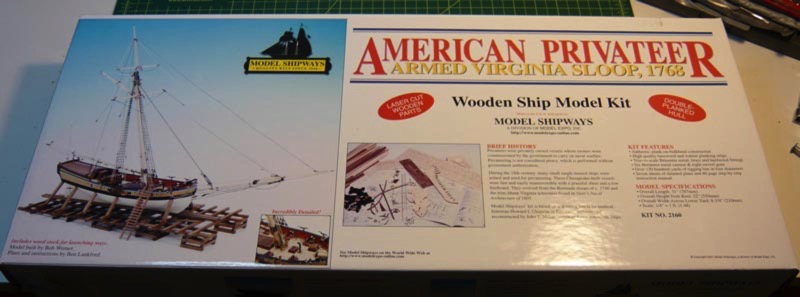

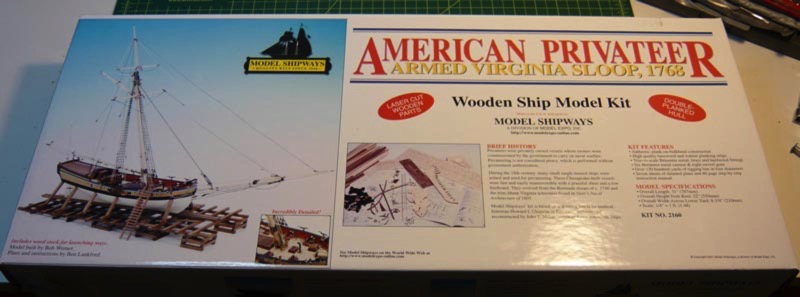

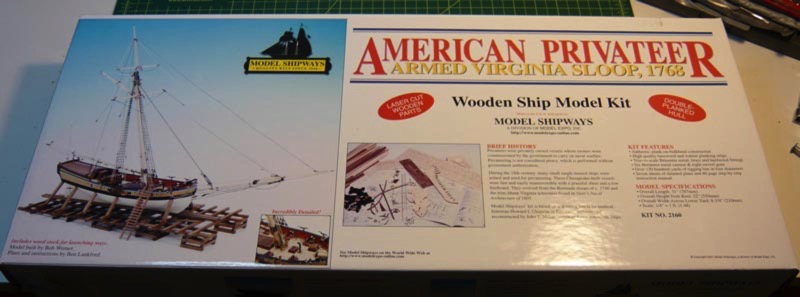

Model Shipways Armed Virginia Sloop

26 - February - 2009 - 20:49

So, my new kit arrived yesterday :-D

Just a little background: I chose this particular kit because the folks on the Drydock Models forums seemed to agree that this was one of a couple good starter boats. Reasons include good instructions, high kit quality, less scratch building, and the availability of kit-specific training materials.

As I mentioned in a previous post, the Lauck Street Shipyard has a very detailed course on building this kit. It goes into an enormous amount of detail and aims to teach many of the tricks of the trade in regards to model ship building. If you are curious, they have the first section of many of the courses available to download and check out for free.

So there is a little background, which brings us up to the new kit. I spent last night picking through the parts and making sure everything was accounted for. After an hour or two of counting parts and measuring wood stock, it seemed everything was in order. There was a tiny bit of damage to one of the very thin laser-cut deck sheets, but it was something that was easily glued back on. I re-glued it last night and it seems to be good as new today, but will take a little sanding once installed later.

I'm now waiting for some organizational items to arrive, to help get my workspace cleaned up a little, and I'm also waiting for the aforementioned building course to arrive. But in the mean time, I have gotten the first section of the course, through which I can read and begin a bit of work. I've also purchased "How to Build First Rate Ship Models From Kits" by Ben Lankford (available from modelexpo-online.com), which I'll be reading as well. All in all, I'm hoping to learn a great deal while building this ship, so that I need much less assistance on the next one.

The box:

The box..... opened!

After all the counting and sorting and such:

Just a little background: I chose this particular kit because the folks on the Drydock Models forums seemed to agree that this was one of a couple good starter boats. Reasons include good instructions, high kit quality, less scratch building, and the availability of kit-specific training materials.

As I mentioned in a previous post, the Lauck Street Shipyard has a very detailed course on building this kit. It goes into an enormous amount of detail and aims to teach many of the tricks of the trade in regards to model ship building. If you are curious, they have the first section of many of the courses available to download and check out for free.

So there is a little background, which brings us up to the new kit. I spent last night picking through the parts and making sure everything was accounted for. After an hour or two of counting parts and measuring wood stock, it seemed everything was in order. There was a tiny bit of damage to one of the very thin laser-cut deck sheets, but it was something that was easily glued back on. I re-glued it last night and it seems to be good as new today, but will take a little sanding once installed later.

I'm now waiting for some organizational items to arrive, to help get my workspace cleaned up a little, and I'm also waiting for the aforementioned building course to arrive. But in the mean time, I have gotten the first section of the course, through which I can read and begin a bit of work. I've also purchased "How to Build First Rate Ship Models From Kits" by Ben Lankford (available from modelexpo-online.com), which I'll be reading as well. All in all, I'm hoping to learn a great deal while building this ship, so that I need much less assistance on the next one.

The box:

The box..... opened!

After all the counting and sorting and such:

1930 Chris Craft Runabout in 1/24 scale

19 - February - 2009 - 21:15

Here are a few images of the last model I finished. This was the first model that I have ever done that had a finished wood construction. When I was a kid I had done a few of the little balsa airplanes that have a tissue out surface, but this boat was a totally different beast.

This kit is a Dumas Boats 1930 Chris Craft Runabout at 1/24 scale. The finished product is about 12" long. It's got a balsa frame and underplanking, with mahogany final planking.

Previous to this kit, almost all of the kits I have built have been plastic. This meant the emphasis was far and away on the painting and cleanup of the plastic. A little filler here, some shading and weathering there and the kits come out nice. This, on the other hand, was a good deal more about the construction, with hardly any painting at all. There was a great deal of shaping and sanding of the raw planks of wood, which, while making a saw-dusty mess of my office, made me feel much more like I had actually BUILT the model, rather than just assembled a kit. There was also a bit of metal cleanup and polishing on the white metal parts, and some working with materials I had not dealt with before (sheet adhesive aluminum).

Overall, I learned quite a bit and whet my appetite for further exploration into the ship building process. As a result, I decided to order up a new ship model (see previous post), with a good deal more complexity, and give that a try.

This kit is a Dumas Boats 1930 Chris Craft Runabout at 1/24 scale. The finished product is about 12" long. It's got a balsa frame and underplanking, with mahogany final planking.

Previous to this kit, almost all of the kits I have built have been plastic. This meant the emphasis was far and away on the painting and cleanup of the plastic. A little filler here, some shading and weathering there and the kits come out nice. This, on the other hand, was a good deal more about the construction, with hardly any painting at all. There was a great deal of shaping and sanding of the raw planks of wood, which, while making a saw-dusty mess of my office, made me feel much more like I had actually BUILT the model, rather than just assembled a kit. There was also a bit of metal cleanup and polishing on the white metal parts, and some working with materials I had not dealt with before (sheet adhesive aluminum).

Overall, I learned quite a bit and whet my appetite for further exploration into the ship building process. As a result, I decided to order up a new ship model (see previous post), with a good deal more complexity, and give that a try.

New model ordered, Model Expo 2009

19 - February - 2009 - 11:06

So I've ordered up a new model to start on: A Model Shipways 1:48 scale Armed Virginia Sloop. After finishing my first wooden model, I decided that I liked it, and that I should give something a little more complicated a try. I think I will also get the course on building this particular model from: http://www.lauckstreetshipyard.com Hopefully this will help me learn many of the tricks of the trade, without making a mess of things.

More info on the model, image source, etc can be had here:

http://www.modelexpo-online.com/product.asp?ITEMNO=MS2160

Also, this weekend is Hobby Expo 2009, up in Petaluma. I only just discovered this the other day, and having never been to one of these things myself, I figured I would go up and check it out. I'm hoping there will be someone there selling some of the Maschinen Krieger (sp?) kits, since they seem to be tricky to find these days.